Each Rhino Rotor model has a corresponding sized water ring.

Adjustable mounting brackets mean easy retrofit onto almost any brand of VSI.

STANDARD MOUNTING MECHANISM

This standard mounting method utilizes a 12 HOLE PLATE which fastens the rotor hub/boss to the rotor shell. Rotor hubs in this configuration come as an optional purchase.

ADAPTED MOUNTING MECHANISM

The adapted mounting method utilizes an ADAPTER PLATE which allows the rotor to be fastened to the rotor hub. In the rotor shell the rotor is being secured to an existing case Cemco T-54 Hub.

The Rhino Rotor employs innnovative Smartip® technnology to dramatically

reduce downtime due to wear part replacement.

Rotor tips can be replaced through the inspection door while the rotor is still

inside the VSI (VSI design dependent) and can be done in three easy steps:

By hand, lift the rotor tip UP.

Pull the bottom of the tip OUT

from the bottom protection plate.

Remove the tip

from the rotor body.

The Rhino Rotor can be supplied with an optional lifting system that makes simple work of removing the entire rotor from the VSI.

The Rotor Lifting Plate is placed underneath the Distributor Plate during rotor assembly.

Part A and B remain in the rotor assembly while Part C is fastened in when needed, replacing the centre distributor bolt.

Access the Lifting Eye Bolt through the top of the rotor.

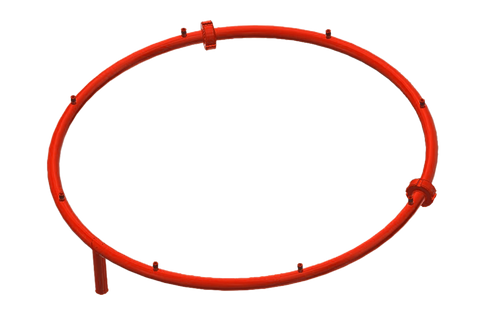

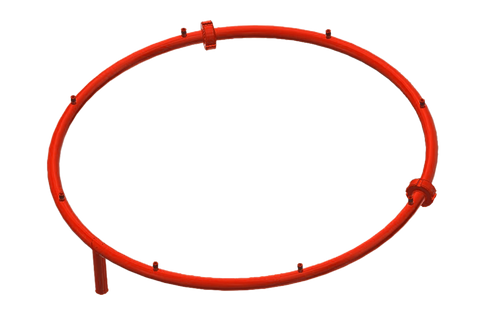

Feed materials containing clay may pack inside the crusher. Severe ‘packing’ may cause wear in the rotor and obstruct throughput. This optional extra is the simplest way to alleviate the effects of ‘packing’ by delivering jets of water to strategic areas within the crushing chamber.

Each Rhino Rotor model has a corresponding sized water ring.

Adjustable mounting brackets mean easy retrofit onto almost any brand of VSI.